Sanitation Standards

It all begins with an idea.

Preventing Food-Borne Illness - in the food business industry, food is fragile and perishable. If food is not handled, stored, and cooked properly, people can become ill. When working with food, your priorities must always be to serve safe food.

Three of the most important ways to keep food safe are:

Perform Temperature Checks: cold food should be served cold (below 40°F), and hot food should be served hot (above 140°F)

Always, always use the proper chemicals to clean your work area and your hands. Learn how to use sanitizer properly.

Wash hands often (see below)

To prevent food-borne illness, change your gloves at least every two hours! Or whenever needed! Wash your hands whenever you:

Go to the restroom (always take off your apron and chef coat before going in)

Touch a trashcan

Touch your face or hair

Touch the floor or trash on the floor

Work with raw chicken, fish, or marinades that involve raw product

Touch any pan or utensil used to work on raw chicken, fish, etc.

Sneeze or cough

Smoke

Sweep the floor

Open a door

Use the POS System and then work with food

* Remember to not take your cellphone with you inside the restroom, using your cellphone in the restroom puts you at risk of catching germs like salmonella, E. coli, and C. Difficile.

Salmonella is a type of food poisoning caused by eating contaminated foods. When you handle a bacteria-infested phone, you’re going to get all that bacteria on your food and possibly become very ill!

E. Coli is an infection that forms from coming into contact with feces or stool from humans or animals. While most strands are harmless, some can cause severe anemia or kidney failure and lead to death.

C. Difficile is one of the most common germs found in a toilet. These bacteria cause symptoms ranging from diarrhea to deadly inflammation of the colon. According to the CDC, nearly 500,000 cases of C. difficile infections were reported in 2011, with almost 29,000 patients facing death after the first month of diagnosis.

The Five Risk Factors for Foodborne Illness

Investigations of foodborne disease outbreaks often identify the following five risk factors that result in foodborne illness:

1. Food held at improper temperature

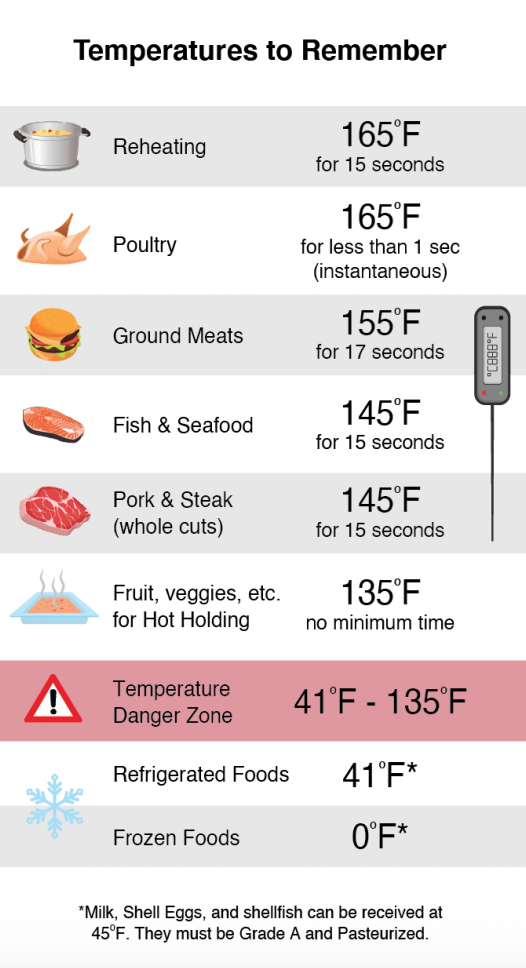

When potentially hazardous foods are maintained at temperatures between 41°F and 135°F, pathogenic microorganisms are able to multiply rapidly. As they grow and multiply, food becomes unsafe.

2. Inadequately cooked or “undercooked” food

Raw foods such as meats, poultry, and fish may already contain many microorganisms. If these foods are not cooked to proper temperatures, the microorganisms will be passed on to the consumer.

3. Contaminated food equipment

Contamination of food may also occur from food equipment that has not been properly cleaned and sanitized. Unproperly washed plates, ramekins, ladles and other utensils may contaminate food and foodborne illness may occur.

4. Food from an unsafe source

Some foodborne illnesses have been linked to foods from an unsafe source such as a non-approved supplier.

5. Poor hygienic practices

When a team member does not practice good personal hygiene, food that they handle is likely to become contaminated. Team member who does not wear clean clothes and apron or use effective hair restraints, working while ill, not washing hands after performing unsanitary task (see above list) are all prime candidates for contaminating food.

Handwashing

Handwashing needs to take place by every team member at a minimum of every 30 minutes, in addition to washing after using the restroom, before putting on new gloves, after handling dirty dishes, cleaning a spill, etc.

Handwashing is one of the most effective things food handlers can do to prevent illnesses. To make sure washing is effective, follow this procedure:

Use hot water that is at least 110°F.

Apply 1 to 2 squirts of soap.

Scrub for at least 20 seconds, making sure to wash in between fingers and under nails.

Rinse thoroughly under running hot water.

Pat hands dry with paper towels. Use the paper towel to turn off the water. Dispose of the paper towel.

Once hands are dry, use 1 to 2 squirts of hand sanitizer. Please remember that using hand sanitizer should be IN ADDITION (not in replacement) to washing hands.

Illness & Sneezing/Coughing

Cough/sneeze away from food and guests. Excuse yourself from the work are

Cover your mouth and nose!

Immediately wash your hands and change your gloves!

Let your manager know if you are sick! If you are contagious, you shouldn’t be working.

Cleaning and Sanitizing

These are the two most essential tasks in a food establishment. Effective cleaning and sanitizing reduce the risk of cross contamination, increases the working life of equipment, minimizes the attraction of insects, and rodents, and reduces the risk of a foodborne disease outbreak. While cleaning and sanitizing are often thought of as one, they are actually two different processes.

Cleaning = removing visible dirt

Sanitizing = reducing harmful bacteria to a safe level (sanitizer is the chemical used to kill bacteria in food)

When you Sanitize, clean the item with soap first, then use a chemical sanitizer as well!

Sanitizing

There are many ways to destroy the microorganisms, but the two most common methods of sanitizing equipment and utensils are with high temperatures or chemicals. High temperature sanitizing is used primarily for warewashing. Chemical sanitizing is also used in warewashing, to sanitize larger pieces of equipment that may not fit in a dishwasher.

The two most common chemical sanitizers used in food service facilities are chlorine and quaternary ammonium compounds

Chlorine-based sanitizers such as bleach, are the most commonly used sanitizers, it is effective in hard water, destroys a wide variety of microorganisms, and leave no film or residue. Chlorine sanitizers are usually used at a concentration of 50 ppm, the water temp should be between 75°F and 115° F and shouldn’t pass 115° F or the solution becomes ineffective.

Quaternary Ammonium Compounds (quats) are a popular general-purpose sanitizer because it is effective at wider temperature and pH ranges. Quats is non-corrosive unlike the chlorine-based, and non-irritating to the skin. Quats is best used at concentrations above 200 ppm and at temperature above 75° F.

Sanitizer Buckets

Follow our current procedures for sanitizer buckets/towels and for sanitizer bottles/towels that clean the tabletops and any surfaces not mentioned above:

● Fill red sanitizer buckets 50% of the way to the top with sanitizer water from the dispenser at the 3-comp sink.

● Run a fresh clean white towel under the sanitizer dispenser to get it wet, then place it in the bucket of solution (make sure a fresh towel is used every time you change the bucket). Only 1 towel per sanitizer bucket is allowed.

● Place a quat/litmus test strip in the solution for 10 seconds to make sure the concentration level is correct.

● Sanitizer buckets are to be changed at least every 2 hours. Change them more frequently if you see they are getting dirty.

Cross Contamination

Cross-contamination occurs when you touch food and then, without washing your hands or changing your gloves, you touch a different type of food, thus transferring bacteria from one product to another. It is especially important to avoid cross-contamination when dealing with raw proteins (e.g. chicken, seafood, beef, etc.).

Walk-in

Improper storage of products in the walk-in can easily lead to cross-contamination. Whenever you put raw protein in the walk-in, make sure it is not being stored above any other product. Juices from that protein can easily drip on items below it and contaminate them. Also, make sure the item is in a sealed container. This will help keep bacteria from spreading. Be especially careful to not contaminate products that are served raw (e.g., cucumbers, lettuce, scallions). Because these items never get cooked, the process that kills bacteria, any bacteria they carry is going to be served to our guests.

Cutting Boards

Cutting two different products on the same cutting board will cause cross-contamination. To prevent this from happening, follow these two simple rules.

1. Always clean and sanitize your cutting board between products.

2. Use the proper colored cutting board.

o Green – produce

o Blue - raw fish/shellfish

o Red – raw meats

o Yellow – raw poultry

o Brown – cooked meats

o White – dairy

Kitchen Prep Sink

Under California Retail Food Code: it only allowed use is to wash, rinse, thaw, and prep foods. Never use for hand washing, cleaning utensils & tools, and disposing of mop water. Sanitize before, after, and between use especially when raw meat is prepared prior to prepping produce or ready-to-eat foods.

Danger Zone

Most bacteria grow between 41° and 135° Fahrenheit. This is called the “Danger Zone.” Food should never be kept between these temperatures. This means that food in refrigerators and on the cold table must always be under 41°F and food on the steam table must always be above 135°F.

Certain foods should be kept above 135°F (e.g. chicken should be 165 degrees). The Steam Times chart posted on the convection steamer outlines the minimum temperatures to which food should be heated. Under NO circumstances can food be served without first being brought up to the proper temperature.

Temp Checks

To ensure food is not in the danger zone, do periodic “temp checks.” A temp check is simply taking the temperature of the food and recording it on the daily Tasting Notes.

How to Do Temp Checks

To do a temp check you need a thermometer, probe wipes, and the Tasting Notes.

Stir the product. Foods cool and heat unevenly. To get an accurate temperature you should stir the food in order to break up any cold or hot pockets.

Insert the thermometer. The thermometer should be inserted deep enough to go through every layer of the food. However, make sure it is not touching the bottom or sides of the pan. You want to take the temperature of the food, not the metal.

Compare and record the temperature on the Tasting Notes. Compare the temperature of the food to the desired temperature on the Tasting Notes. If an item is not at the proper temperature, bring the item to temperature in the convection steamer by incrementally heating and temperature checking (ensure that you do not overcook the item by heating in small increments and taking the temperature after each heating). Record the temperature in the proper place on the Tasting Notes.

Sanitize the thermometer. After you remove the thermometer from each product, wipe it thoroughly with the probe wipes before placing it in another product. Sanitizing the thermometer will prevent cross-contamination.

How to Calibrate the Thermometer

Thermometers should be calibrated (checked for accuracy) on a regular basis and after being dropped or jarred. To calibrate a thermometer...

Fill a clean, plastic cup with 1⁄2 water and 1⁄2 ice.

Insert the thermometer in the slush making sure the tip does not touch the side or bottom of the cup.

Wait until the reading is steady.

If the thermometer is digital and does not read 32 degrees, change the battery. If the thermometer is a simple, pocket one, turn the nut until the needle reads 32 degrees.

Cooling Product

When cooling the product, you want it to pass through the danger zone as quickly as possible (that is, you want to get it from above 135 degrees to below 41 degrees in the shortest time you can). To do this:

· Transfer hot food into sanitized 2” hotel pans. Using large shallow pans and spreading the food out will help it cool faster.

· Never put a lid on food that is cooling. The lid will keep the heat trapped near the food.

· If possible, place the pan on ice.

At the end of the night, when you have a lot of product to cool, turn off the steam table, drain it, and fill it with ice. That will give you enough room to ice down all of the carry-over food. During service, you may not have the room to ice down hot products. If this is the case, put food directly into the walk-in. For example, after making a batch of roasted veggies in the morning, transfer them into sanitized 2” hotel pans and put them in the walk-in uncovered to cool. Cover the product when it has cooled.

Thawing Procedures

In Cold Water – this method typically takes 20-30 minutes per pound of food and requires some planning and preparation. Cold water thawing is meant to keep the surface of your food cool enough that the bacterial growth stays slow, allowing the food to slowly, and safely thaw all the way through. It is important that you keep the temperature of the water consistently at or below 70°F. Refresh the water every 30 minutes or so.

In Cold Running Water – one way to keep the water cold without having to continuously watch over it is to fill a bowl with cold water and leave the tap water running over the food as it thaws. This does require a lot of water, but it will keep the surface temperature of your food from growing bacteria too rapidly. Keep the food in its original container or in a plastic, resealable bag to protect the kitchen sink and counter from germs.

In the Refrigerator – this is the safest method for thawing, especially when thawing whole food items. It takes the longest amount of time so planning ahead is the key! Depending on the type of food you are thawing, 5 lbs. can take 24 hours to thaw. While this method definitely takes some planning ahead, there are many upsides to thawing frozen food this way:

1. The refrigerator keeps the food safe from bacterial growth the entire time it thaws.

2. You won’t need to keep watch over the food.

3. You helped save some water resources.

Working with Seafood

When working with seafood never take the product out of the walk-in before you are ready to work with it. You want to minimize the amount of time the fish is at room temperature because seafood is especially vulnerable to bacteria growth. Always keep the product over ice (even when it is in the walk-in). For example, when you cut salmon and cubed tuna, keep the filets you are not presently working with wrapped in plastic and on ice, and immediately transfer the cut portions into a 1/6 pan on ice.

Product Rotation

F.I.F.O.

To minimize food spoilage, you should always use the oldest product available (of course, if the product is spoiled you should let your manager know and use a fresh batch). This method of food rotation is called First In/First Out (FIFO). To ensure FIFO is followed, always put new products behind old products on shelves and in refrigerators.

Food Labels

To make using FIFO rotation easier, every product should have a food label sticker on it. This includes everything in the walk-in, freezer, dry storage, grill drawers, and refrigerators under the line. Food Labels/Day Dots are color-coded stickers that signify what day of the week the product was prepped or received. The sticker should be facing out, so it can easily be seen. In addition, if you think batches could get mixed up, place a “Use First” sticker on the older batch.

Safety Procedures

It all begins with an idea.

The safety of your guests and team members is critical to the success of your organization. Your commitment to providing a safe environment for both your greatest asset (your staff) and your guests, has to be on top of your priority as a restaurant operator. It is essential that each Manager, Supervisor, and Team Member take an ongoing interest in the prevention of accidents and provide leadership that will inspire everyone to work in a safe manner each day. You have to stress enough the need to be aware of opportunities to improve the safety of your workplace.

Each member of your team is responsible to report any situation that he/she considers unsafe. It’s everyone’s obligation to make a safe and better workplace by reporting unsafe conditions and practices.

Position-Specific Safety Training:

Different positions require different safety procedures (i.e. Prep requires proper cutting techniques to avoid accidents). Position-specific training is completed before any new team member begins his/her position at your company. Your staff should follow the guidelines set forth by your company and including both preventative measures and first aid procedures.

Safety Standards

Most accidents can be avoided by simply being more careful. We can all help to make our workplace a safe and healthy place to work just by following these basic safety principles.

Don’t ever operate a piece of equipment until your trainer has demonstrated and communicated all safety issues.

Immediately report to a manager any unsafe or potentially hazardous condition, such as broken or splintered chairs or tables, defective equipment, unsafe tools or knives, or broken glass.

Keep aisles and passageways clean and free from obstruction. Do not let any objects remain where someone can trip on them.

Don’t ever rush so much that you risk hurting yourself or others. Hurrying is a major cause of accidents.

Lifting & Carrying

Before attempting to lift an item, first, determine if you can do so safely. If you are not sure you can easily lift it alone, ask for help!

When you lift a heavy object, lift with your legs rather than your back.

Bend your knees, keep your arms and back straight, and your chin in.

Lift by gradually pushing up with your legs. Avoid jerky motions.

Lift without twisting. Turn your feet, not your hips or shoulders.

Keep objects close to your body.

Utilize 2 or 3 people to lift the object if it is awkward or too much for 1 person

Slipping and Falling

Pick up everything spilled or dropped on the floor

Remove or report any object blocking an aisle

Walk, never run

Wear sensible shoes with non-skid soles and moderate-height rubber heels

Use a stepladder for hard-to-reach things. Chairs, crates, and other makeshifts are dangerous

Report any leaky or dripping equipment

DON’T IGNORE any potential slipping danger. If you cannot fix the situation immediately, cover the dangerous spot with a Wet Floor sign, and notify your Manager. Never leave a dangerous situation unattended.

Using Knives

If you have not used knives or are a beginner...let your Manager and trainer know so you can receive the proper training before you begin using any knife

Always wear a cutting glove

Always cut away from your body

Always use a cutting board

Keep knives sharp

Carry a knife by holding it at your side with the point down to the floor and the blade facing to the rear (don’t press the knife against your leg)

Never leave knives in a sink, they could cause cuts to anyone reaching into soapy water

Don’t try to catch a knife if it falls...let it fall. Then pick it up.

Equipment Use

Make sure you know how to correctly operate every machine you use

Know the hazards of the equipment before using it

Make sure the machine is turned off before you plug it in

Before cleaning equipment, ensure the unit is off and unplugged

Storage of Chemicals

Chemicals should be stored in a designated area where they cannot contaminate or spill onto foods, linens, dishes, utensils, food equipment, or any food contact surfaces. Many chemical manufacturers recommend that chemicals be stored in a cool, dry location. The product label should be reviewed for specific storage instructions. Chemicals must always be stored at least 6” off the floor and in containers that clearly identify their chemical contents.

Chemical Usage and Safety

It is important to always follow the manufacturer’s instructions when using chemicals to clean or sanitize. Cleaners and sanitizers will be most effective when used at concentrations and temperatures specified by the chemical manufacturer. This information can usually be found on the product label. Occupational Safety and Health Administration (OSHA) requires that this information be available to employees at all times. To satisfy this requirement, chemical manufacturers produce Safety Data Sheets (SDS)

The Safety Data Sheets contain:

The manufacturer’s contact information

Physical and chemical properties of the product

Information about the safe use and handling of material

Fire, explosion, reactivity, and health hazard information

Information about personal protective equipment that may be needed

Emergency procedures and first aid

The date the SDS was prepared

In addition, OSHA requires that all employees be trained about the chemicals used in the facility. This training should include the safe use of the chemicals, any hazards associated with the chemicals, the location of the SDS binder, and how to read an SDS sheet. The person in charge should have a written

Buffet Service Standards

It all begins with an idea.

Running a buffet poses certain food safety risks that you must manage to protect your customers from food poisoning. Buffets often include displays of hot and cold food, as well as a food held at room temperature; many of these foods (e.g. seafood, meat, dairy products) can harbor dangerous bacteria that can multiply rapidly in the right conditions, and customers themselves can often contaminate food without realizing it.

5 Rules for Buffet Food Safety

Follow these five rules to prevent food poisoning or allergic reactions from happening in your buffet-style restaurant.

To prevent a serious food safety incident from happening in your buffet-style restaurant, follow the five rules below:

1. Keep food out of the Temperature Danger Zone

All potentially hazardous foods (also called high-risk foods) must be displayed in hot or cold displays outside of the Temperature Danger Zone (4°C to 60°C*), which is the temperature range in which bacteria and other dangerous microorganisms can multiply rapidly.

High-risk foods include the following (and any dish containing the following):

meat/poultry/fish/shellfish

eggs/egg products

dairy products

leafy greens and other produce

For food items being held in the hot food zone, remember to:

stir items frequently to evenly distribute heat throughout the food

check food temperatures often

use a cleaned and sanitized thermometer to check food temperatures

calibrate your thermometer before use

If you’re using a probe thermometer to check hot food temperatures, insert the thermometer into the thickest part of the food (avoid bones and do not touch the thermometer to the sides or bottom of the display dish). For cold food items, if you are unable to stir the product, simply insert the thermometer into the thickest part to take an accurate reading.

Use labels or another system to indicate how long food has been on display, and when the last temperature check was performed; you can use any system that works for you, as long as it effectively communicates this information to all food service employees on duty, who can take corrective action if required.

If you must hold food at room temperature, be sure to discard any high-risk foods that have been on display for two hours or longer. To reduce food waste, you’ll want to prepare and display food in small batches that can be used within a two-hour timeframe.

2. Supervise and monitor self-service areas

The funny thing about buffet food safety is that the customers themselves often pose the greatest risk — to themselves and to other customers. On the other hand, Food Handlers are trained in proper food handling practices; many have completed a food handling course and obtained a food handling certificate from a recognized provider.

Food Handlers take precautions to prevent food contamination, whereas the public, who have not undergone food safety training, may not. That means that any man, woman, or child eating at the buffet could contaminate their own food and everybody else’s.

To save the customer from him or herself, it’s important that you supervise and monitor self-service areas. Allocate at least one staff member per shift (or per station) to supervise the buffet and train them on the steps to take if they notice a possible contamination incident.

It can be challenging to maintain careful supervision without making customers feel uncomfortable, so you’ll want to allocate these tasks to staff members with good customer service skills, who won’t be too intrusive.

We also recommend putting out signs to remind customers to:

use only the utensils provided for each food item

not use their fingers to touch any food items (“Please use the tongs provided.”)

use clean plates, cutlery, and napkins when they revisit the buffet for refills

supervise children who are serving themselves at the buffet

You don’t want customers to feel like they are under a microscope, but signage can help to remind customers that their actions can impact the health and safety of others. They will likely appreciate your efforts to minimize contamination risks — after all, who knows if the person standing next to them in line washed their hands properly?

3. Have at least one serving utensil for every food item

Using the same serving utensils for different foods, or touching food items with your bare hands, can cause cross-contamination; in a food setting, cross-contamination refers to the accidental transfer of contaminants to food, making it unsafe to eat.

In a full-service restaurant or other food business, cross-contamination is controlled by trained Food Handlers like chefs, cooks, and servers, who follow food safety protocols — such as using different utensils for different types of food — to minimize the risk of cross-contamination.

In a buffet-style restaurant, when customers use the same serving utensil to pick up different foods, or when they use their hands to pick up food items, they can:

introduce food allergens into dishes that should not contain them

transfer bacteria from raw food (e.g. sushi, sashimi) to ready-to-eat food (e.g. bread, cakes, pastries)

transfer bacteria or viruses from their hands to food

Having one or more serving utensils for each food item discourages customers from using the same serving utensil (or their fingers) to pick up different food items.

It’s important to stay on top of this; have cleaned and sanitized utensils ready to replace those in need of cleaning so that the food item is never left without a serving utensil. Even a short delay could result in a customer “winging it” with whatever is close at hand.

Remove any food or utensils that you notice have become contaminated from service and replenish them with fresh items.

4. If in doubt, throw it out

Food safety isn’t an exact science; foods that are contaminated with harmful bacteria and other pathogenic microorganisms (e.g. viruses, parasites) may not look, taste or smell any different from foods that are safe to eat. Trace amounts of food allergens are also tasteless and impossible to detect with the senses.

So how do you know for sure if food is safe to eat or if it needs to be thrown out? The short answer is you don’t always know. You can’t always tell if food is safe or not, which is why it’s important to understand the fundamentals of safe food handling and to follow food safety best practices.

For example, it's a best practice to throw away any high-risk foods from a buffet or self-service facility that haven't been used within two hours; this is because bacteria and other pathogens will have had time to multiply to unsafe numbers.

Remember that hot holding equipment is not designed to reheat food or to bring it to temperatures above 165°F, which is necessary to destroy harmful bacteria.

5. Take practical steps for food safety

While there are many potential sources of contamination in a buffet, there are several practical steps that can be taken to protect food and utensils from contamination.

For example:

Cover all food items with lids (whenever possible).

Use sneeze guards over buffet areas to prevent bacteria from sneezing or saliva from reaching the food.

Ensure that the handles of serving utensils don't touch food items, as bacteria from customers’ hands can get into it.

Keep raw food that will be used for cook-to-order items well away from pre-prepared or cooked foods.

Never add fresh food to old batches of food.

Never reuse food that has been sitting on a buffet table (even if it’s only been there a short time).

Keep cutlery and napkins under cover or well away from the food.

Clean and sanitize food trays frequently.

Ultimately, the best way to manage food safety hazards in your business is by training your food service employees. When Food Handlers understand why food safety is important, how to handle food safely, and how to prevent foodborne illness and other health risks, your customers (and your business) will benefit.

For how long can I safely hold food on a steam table?

Here it’s important to distinguish between how long you can hot-hold food and how long you should hold it. Under the food code, there is no set time limit for how long a food can be held, provided it maintains its temperature above the danger zone.

But just because something is safe to eat does not mean it should be eaten. Some foods, such as chili, for example, do well in hot-holding and may even be enhanced as flavors meld and some water evaporates over a period of a couple of hours. Other foods such as vegetables, eggs, fish, or baked items such as pancakes do not age well in a hot-holding environment.

Ideally, each item on your buffet or hot-held in the kitchen will have an established time limit as part of your standard operating procedures, considering not only the safety of the item but also its quality. Small digital timers can help you remember to refresh each item as it nears the end of its optimal life.

As a best practice for quality, safety, and waste reduction, prepare steam table items in smaller batches as needed rather than loading up the table and letting things devolve over a long period.

Steam tables vary widely in their settings. Some have words like low-medium-high, some have ranges of 1 (low) to 10 (high), while others may be 1 to 7. Some steam tables have the actual temperature settings.

The key question is not what setting you are using for your table, but what is the temperature of the food you are holding? Typically, hot food needs to be held above 135° F (exact temperatures may vary by county). The key is to use a good thermometer to frequently take the temperature of the hot-held food and adjust the steam table accordingly. In addition, you need to stir frequently to distribute the heat and take readings at the top edge of the held food, rather than the bottom, which is closest to the heat source. If the extra moisture would not affect quality, using a lid on the steam table can help with even, safe temperatures.

Holding above the minimum temperature is fine as well, but then you have to consider product quality issues. Some foods like broth-based soups hold well on the maximum setting. Others, like food containing eggs, you’ll want to hold closer to the minimum allowable.